Choosing the Right Materials for Multi-Function Polishing Equipment in Metallurgical Analysis

2026-02-05

Application Tips

This article explores key factors in selecting durable and efficient multi-function polishing equipment for metallurgical sample preparation. It emphasizes functional integration, adjustable speed ranges, motor power optimization, and material selection for both performance and longevity. Real-world application cases and technical insights demonstrate how proper equipment choice improves workflow efficiency and consistency. A robust after-sales support system further ensures user satisfaction and long-term reliability—offering practical guidance for informed purchasing decisions in metallurgical laboratories.

Why Material Matters: Choosing the Right Multi-Functional Polishing Equipment for Metallurgical Analysis

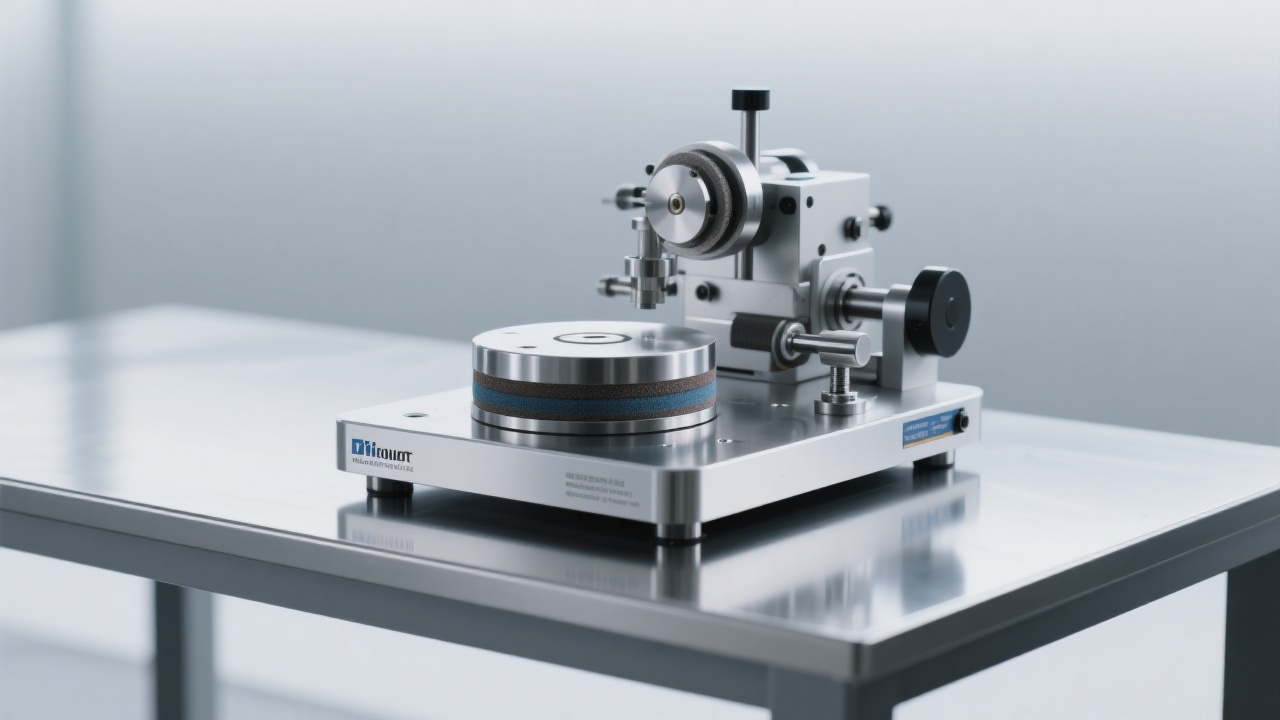

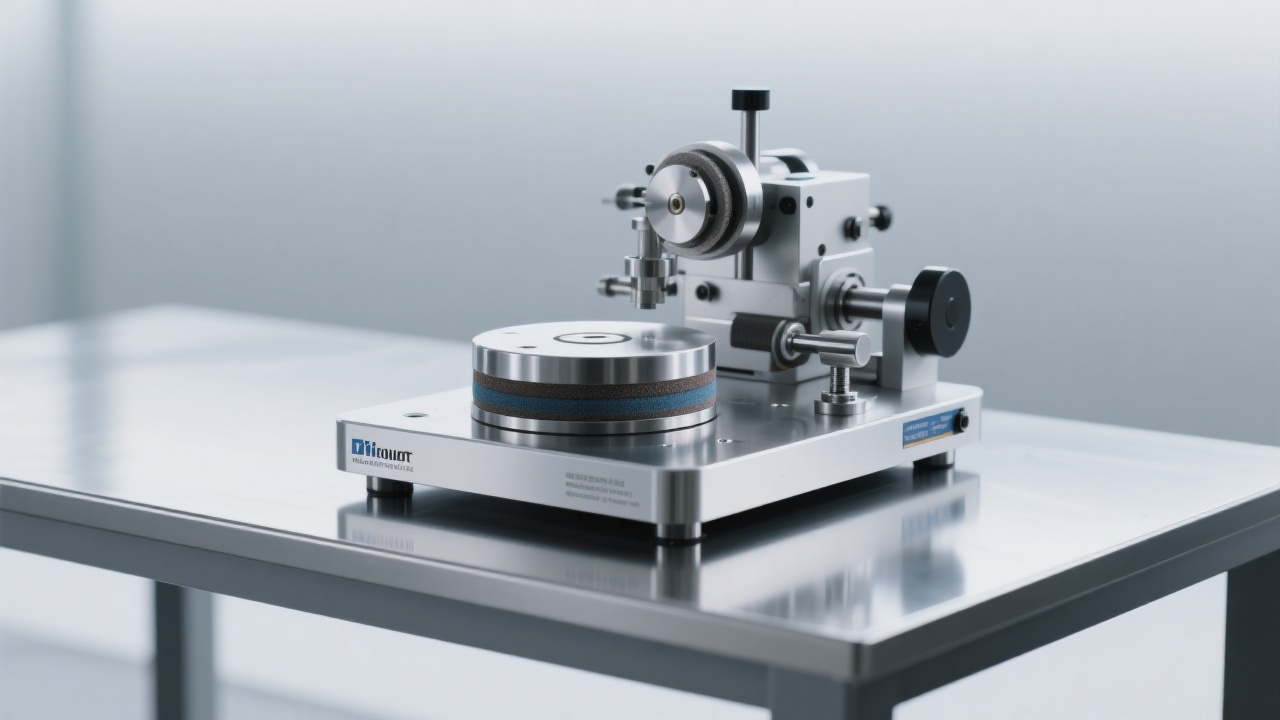

In metallurgical labs around the world, precision starts with preparation—and that begins with polishing. A high-performance multi-functional polishing machine isn’t just a tool; it’s an investment in accuracy, consistency, and long-term productivity. But how do you choose one that truly meets your needs?

The Core Metrics That Define Performance

When evaluating a polishing system, focus on four critical factors: functionality integration, motor power, speed range, and material durability.

- Integrated Functions: Machines combining grinding, polishing, and final finishing reduce workflow interruptions by up to 40% (based on lab efficiency studies from 2022–2024).

- Motor Power & Speed Range: Look for motors rated at least 300W with adjustable speeds from 100 to 2,000 RPM—ideal for both soft metals like aluminum and hard alloys such as stainless steel.

- Structural Materials: Aluminum alloy frames offer better corrosion resistance than plastic housings, while stainless steel platters ensure longevity under frequent use.

Real-world testing shows that equipment built with durable materials lasts 3x longer in high-volume labs compared to cheaper alternatives—reducing downtime and maintenance costs significantly.

Case Study: Efficiency Gains in a European Steel Research Lab

A leading metallurgy lab in Germany switched from a basic single-function unit to a fully integrated polishing system. Within six months, they reported:

| Metric |

Before Upgrade |

After Upgrade |

| Sample Prep Time per Batch |

45 min |

28 min |

| Maintenance Frequency |

Every 3 weeks |

Every 2 months |

| Operator Satisfaction Score |

7.2/10 |

9.4/10 |

Don’t Underestimate the Value of After-Sales Support

Even the best machines need support. Reliable manufacturers provide:

- Free remote diagnostics via email or video call

- On-site service within 48 hours in major regions

- Extended warranties (up to 3 years) for key components

Our clients who prioritize post-purchase care report 70% fewer operational disruptions over 12 months—a clear sign that support isn't optional—it's essential.