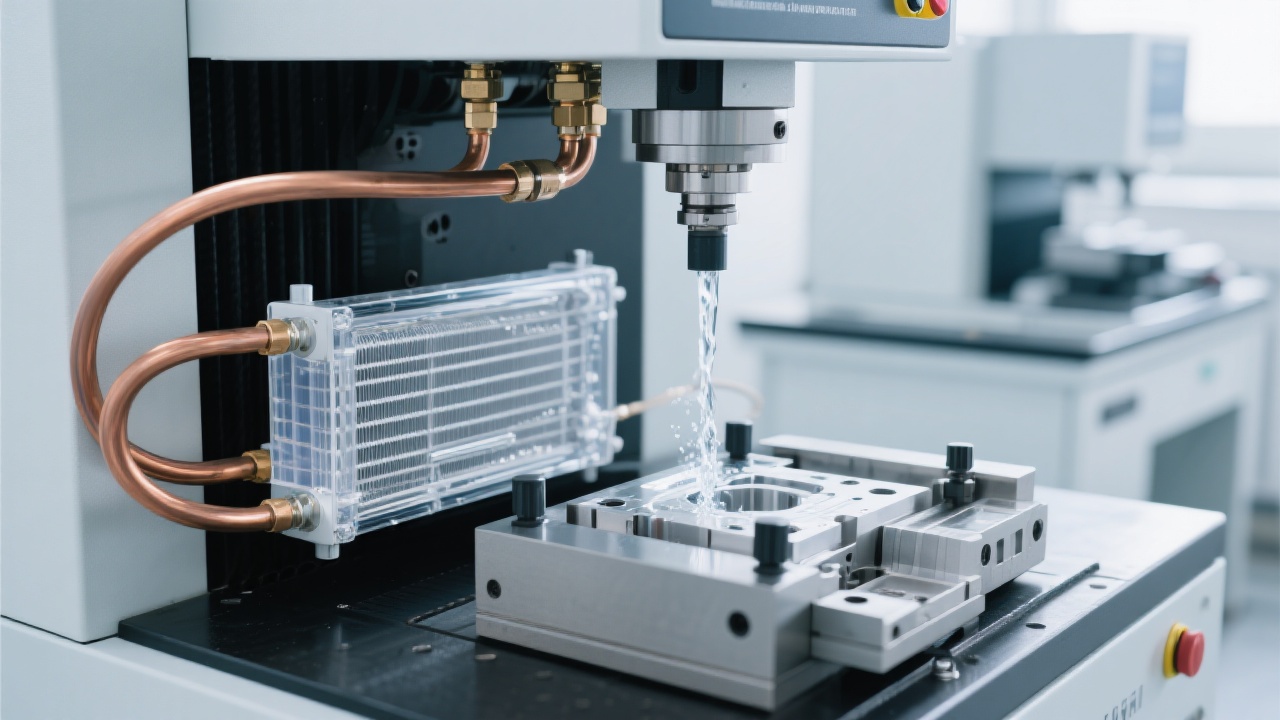

Selecting the right polishing equipment for metallurgical analysis sample preparation is a critical decision that shapes the quality and reliability of your results. The MP-2B precision polishing machine stands out by integrating pre-grinding, grinding, and polishing functions into a single versatile device. This article explores the core technical advantages of the MP-2B, focusing on motor power, variable speed control, material robustness, and structural design—factors that directly influence its adaptability and operational efficiency in metallurgical labs.

The MP-2B is equipped with a powerful 550W motor capable of driving speeds from 50 to 1000 revolutions per minute (RPM) via seamless stepless speed regulation. This wide speed range is pivotal for adapting to the spectrum of metal samples encountered in metallurgical laboratories, from soft aluminum alloys to hardened steel specimens.

Why does this matter? Lower RPM speeds minimize surface overheating and prevent microstructural damage during the initial cutting and grinding stages, especially on softer or more delicate materials. Conversely, higher RPMs expedite the polishing process for harder metals, improving throughput without compromising surface integrity. Studies aligned with ISO 4517 confirm that maintaining optimal speeds tailored to material hardness prevents deformation and ensures consistent metallographic results.

Crafted with a high-strength ABS outer shell, the MP-2B surpasses common plastic alternatives in durability and longevity. ABS provides exceptional impact resistance and heat tolerance, crucial in laboratory environments where equipment faces continual mechanical stress and chemical exposure.

Internally, the machine's precisely engineered framework guarantees operational stability. This prevents vibrations that may cause uneven polishing, thereby enhancing precision and reproducibility. The superior construction significantly reduces maintenance downtime, ensuring laboratories can rely on continuous, high-quality sample preparation without frequent repairs.

Traditional metallographic preparation often involves separate machines for pre-grinding, grinding, and polishing—each requiring manual transfer of samples, increasing the risk of contamination and errors. The MP-2B’s multifunctional integration consolidates these steps, reducing operator intervention and minimizing processing time.

In practice, facilities such as steel mills and university research labs have documented workflow improvements exceeding 20%, attributed to reduced equipment switching and enhanced process continuity. This translates directly into higher sample throughput and more consistent metallographic analysis outcomes.

Beyond hardware, the MP-2B is backed by a professional after-sales service system encompassing onsite installation guidance, remote technical support, and timely maintenance response. These service layers safeguard laboratory operations against unforeseen downtimes, ensure rapid troubleshooting, and maintain peak equipment performance.

Clients investing in the MP-2B report a superior return on investment thanks to reduced operational disruptions and product lifecycle extension—key considerations especially for high-volume metallurgical testing centers.

Selecting polishing parameters—speed, abrasive type, and pressure—is underpinned by the sample’s metallurgical properties. The MP-2B’s adjustable speed coupled with its integrated design allows fine-tuning for various sample hardness and textures without the need for multiple devices.

Below is a reference table mapping typical material hardness against optimal rotational speed ranges, illustrating how the MP-2B’s versatility accommodates diverse metallurgical sample profiles.