Common Metallographic Sample Preparation Issues in Mechanical Manufacturing and Multi-Stage Polishing Techniques

2026-02-14

Application Tutorial

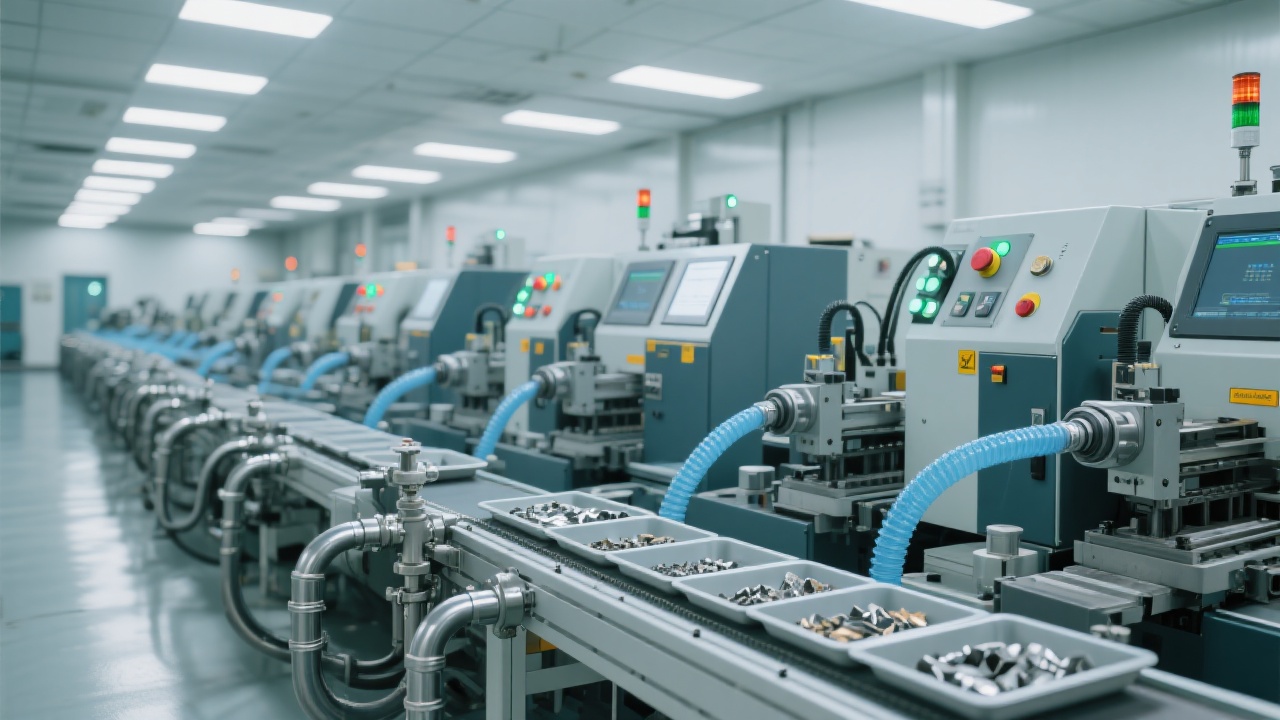

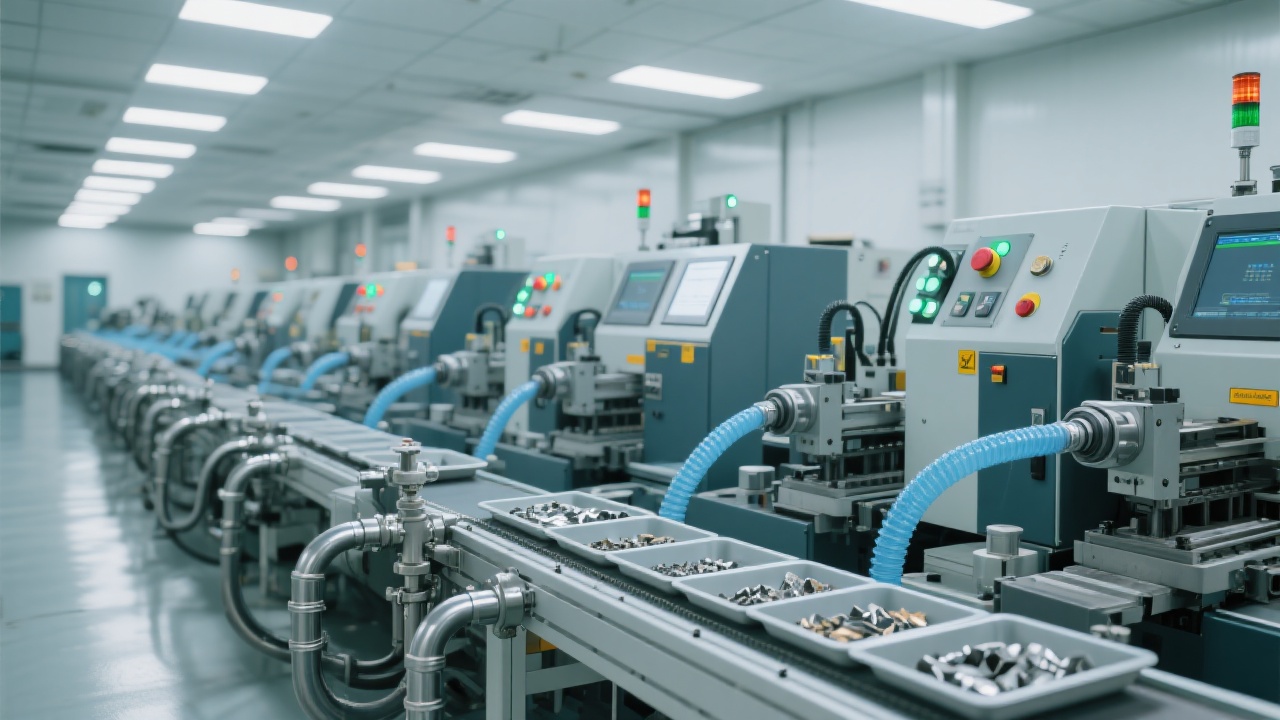

Are you struggling with scratches, edge chamfering, or uneven surfaces on your metallographic samples? This article analyzes common challenges in metallographic sample preparation within mechanical manufacturing and metallurgical testing industries. It explores root causes across three key dimensions: equipment performance (grinding wheel precision, fixture stability), operational practices (choice of abrasive fluids, speed adjustment), and environmental controls. Practical solutions include implementing a multi-stage polishing approach (coarse grinding → fine grinding → final polishing), routine calibration of worktables, and using specialized clamps for thin specimens. Aligning with ISO international standards, we guide you through establishing standardized operating procedures (SOP) to enhance sample consistency, certification compliance, and overall metallographic preparation efficiency.

Why Do Your Metallographic Samples Always Show Scratches, Beveled Edges, or Uneven Surfaces?

In the mechanical manufacturing and metallurgical inspection industries, achieving flawless metallographic sample preparation is often more challenging than anticipated. Nearly 80% of surface scratches stem from improper abrasive liquid selection or inconsistent polishing speeds. These recurrent issues not only delay quality assurance but also inflate operational costs due to repeated sample reworks.

Understanding the Root Causes: A Three-Dimensional Analysis

Before remedying the imperfections in your metallographic samples, it's crucial to break down the contributing factors into three core dimensions:

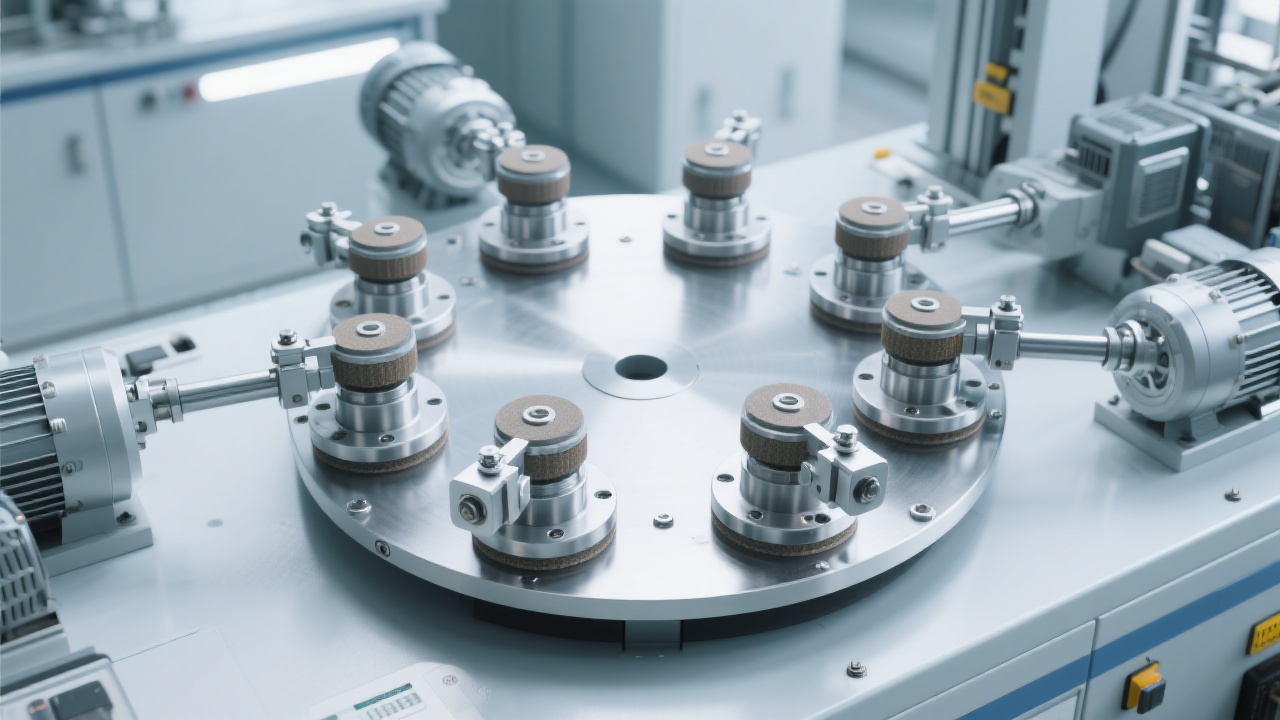

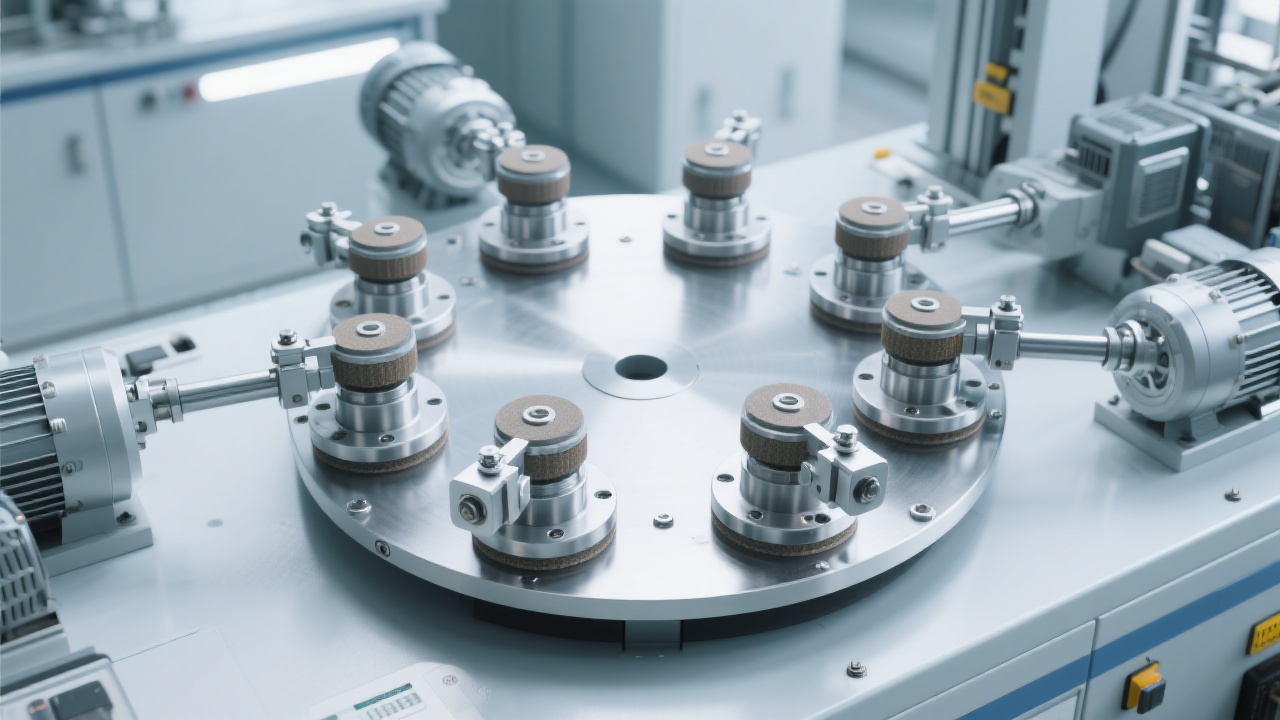

- Equipment Factors: The precision of the grinding wheel and stability of the fixture significantly influence surface integrity. A slightly warped polishing disk, for example, can cause uneven material removal leading to surface ripples or edge beveling.

- Operational Habits: Selecting suitable abrasive fluids and matching rotational speeds per grinding stage are critical. Incorrect fluid viscosity or incompatible speed results in micro-abrasions or sample heating, damaging the specimen’s microstructure.

- Environmental Control: Consistent temperature and humidity levels, along with a clean workspace, prevent contamination and ensure repeatability of the polishing process.

Concrete Solutions for Common Metallographic Sample Defects

Address each issue systematically with these practical strategies:

- Equipment Calibration: Conduct a weekly inspection of fixture tightening and monthly measurement of polishing disk flatness using dial gauges. This reduces edge beveling which accounts for approximately 25% of failed samples.

- Multi-Stage Polishing Strategy: Implement a three-phase process—coarse grinding, fine grinding, and final polishing—to progressively remove defects without introducing new scratches.

- Abrasive Fluid Selection and Speed Matching: Use manufacturer-recommended polishing liquids with viscosities tailored to metal type, coupled with optimal spindle speeds ranging between 150 to 300 RPM depending on polishing stage.

- Environmental Consistency: Maintain workshop temperature at 20–25°C and relative humidity between 45–60%, and institute a daily cleaning protocol to minimize contamination.

Building a Standardized Operating Procedure Aligned with ISO Standards

Adhering to ISO 17025 and ISO 4967 standards ensures your metallographic preparation process is reproducible and trustworthy. Your SOP should detail:

- Stepwise multi-stage grinding and polishing procedures with defined parameters.

- Regular calibration schedules and inspection records.

- Clear protocols for fluid use, spindle speed settings, and environmental checks.

- Quality control checkpoints with acceptance criteria for surface defects.

Embrace a culture of documentation and compliance to not only meet certification requirements but also improve internal knowledge transfer and training effectiveness.

Avoiding High-Frequency Errors: A Practical Checklist

Below is a summary of common pitfalls and corrective measures that improve sample quality and reduce costly reworks:

| Frequent Error |

Cause |

Improvement Action |

| Surface Scratches |

Inappropriate abrasive fluid or excessive speed |

Select matched fluids; adjust RPM per stage |

| Beveled Edges |

Loose fixture or warped grinding wheel |

Tighten fixtures weekly; calibrate polishing disk monthly |

| Surface Unevenness |

Environmental fluctuations and contamination |

Control temperature/humidity; daily cleaning routines |

Your Experience Matters: Share Your Metallographic Preparation Challenges

Have you encountered persistent scratch issues or edge deformities in your samples despite using advanced equipment? What strategies have you found effective? We invite you to share your challenges and solutions in the comments below. Your insights help build a stronger professional community focused on quality and innovation.