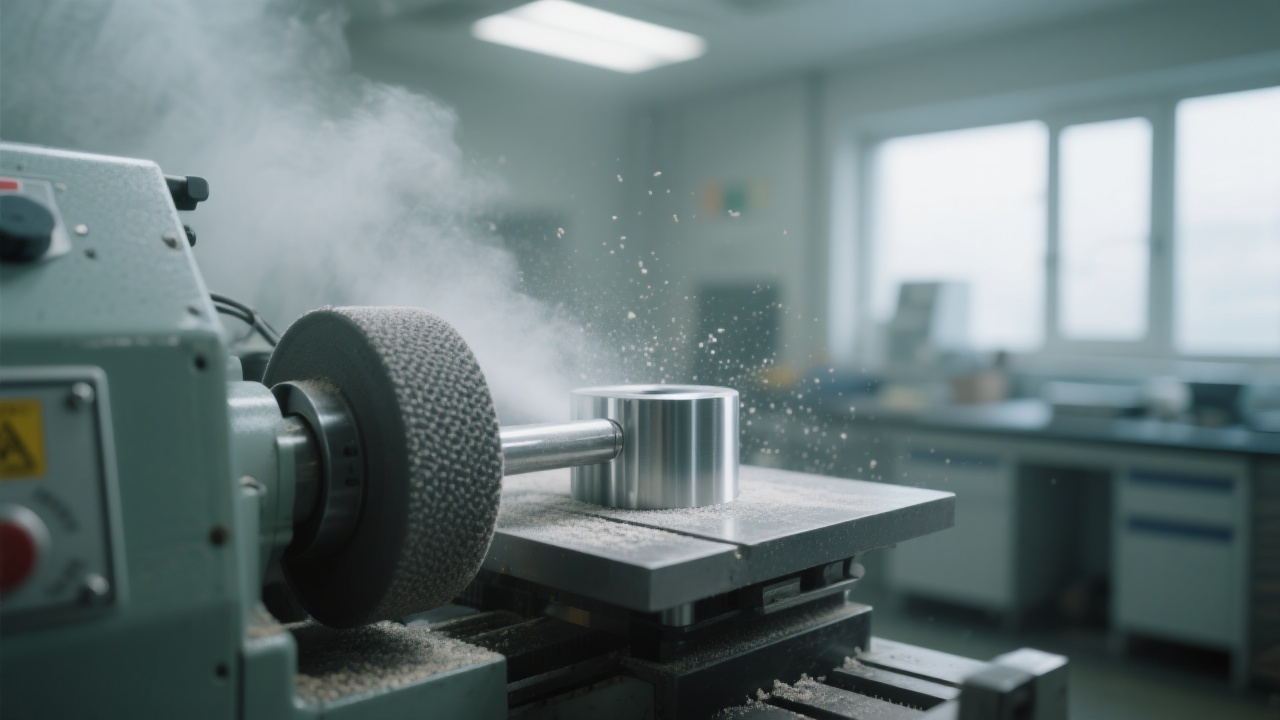

Metallographic sample preparation is foundational to precise materials analysis, demanding meticulous attention throughout every step. Among these, the cutting stage plays a pivotal role in determining the quality and integrity of samples. This guide delves deeply into the optimization of cutting parameters using the Laizhou Jincheng SQ-100 Manual Precision Metallographic Cutting Machine, focusing on rotational speed, cutting pressure, and cooling efficiency to prevent sample deformation and thermal damage while ensuring superior downstream polishing results.

The metallographic preparation process involves six essential stages: sampling, mounting, cutting, cleaning, grinding, and polishing. Precision in cutting is critical because errors here can propagate through subsequent steps, degrading microscopic analysis quality. Each material type—metal alloys, ceramics, and composites—presents distinct challenges requiring tailored cutting parameters.

Optimal cutting hinges on a scientifically balanced set of parameters. Below is a breakdown of the core factors:

Improper parameter settings trigger two primary issues:

Combating these requires an integrated approach: precise force control, speed moderation, and effective cooling. The SQ-100 integrates a high-efficiency cooling system that circulates coolant steadily, maintaining blade and sample temperatures below 30°C during operation.

| Inspection Item | Requirement | Recommended Action |

|---|---|---|

| Blade Condition | Sharp, free from nicks | Replace if worn or damaged |

| Coolant Level and Quality | Adequate and clean | Refill or replace coolant as necessary |

| Sample Mounting | Secure and stable | Re-mount if loose |

| Parameter Settings | According to material specifications | Verify RPM, pressure, feed rate |

An aluminum alloy sample was processed using 250 RPM rotational speed, 1.2 kgf/mm² cutting pressure, and 0.03 mm/s feed rate with continuous coolant flow. The cut surface exhibited minimal burrs and no thermal discoloration. In contrast, a ceramic composite required a reduced speed of 120 RPM and a lighter pressure around 0.8 kgf/mm² to avoid microfractures. Both scenarios leveraged the SQ-100’s precise parameter controls and cooling system, illustrating versatility across material classes.

The SQ-100 stands out with its:

Frequent mistakes include setting excessive speed, applying uneven cutting pressure, neglecting coolant maintenance, and ignoring blade wear signs. Employing the comprehensive pre-cutting checklist and adhering to parameter guidelines fosters standardized workflows and reproducible outcomes. Additionally, timely blade replacement based on usage cycles (typically every 100+ cuts depending on material) prevents quality degradation.

Establishing a standardized metallographic cutting protocol supported by precise parameter control and consistent cooling practices directly elevates sample preparation quality. The SQ-100’s integrated design supports this by combining technological innovation with ease of use. Laboratories adopting this machine observe enhancements in throughput, reduced rework rates by up to 30%, and improved microscopic analysis accuracy—critical metrics for advancing materials research and quality assurance.

| Material | Optimal RPM | Cutting Pressure (kgf/mm²) | Feed Rate (mm/s) | Coolant Requirement |

|---|---|---|---|---|

| Aluminum Alloy | 200-300 | 1.0 - 1.5 | 0.02 - 0.04 | High flow, clean coolant |

| Ceramic Composite | 100-150 | 0.5 - 0.8 | 0.01 - 0.02 | Very high cooling to prevent cracking |

| Metallic Alloys (Steel) | 250-320 | 1.2 - 2.0 | 0.03 - 0.05 | Consistent coolant circulation |