In the field of metallographic analysis, ensuring the compliance of metallographic grinding and polishing equipment with international standards is crucial for accurate and reliable results. This article delves into how to determine whether metallographic grinding and polishing equipment meets international standards, focusing on the key detection indicators of ASTM E3 and ISO 14609 standards.

ASTM E3 and ISO 14609 play vital roles in the application of metallographic grinding and polishing equipment. ASTM E3 provides a set of standard practices for preparing metallographic specimens, which is widely recognized in the United States and many other countries. ISO 14609, on the other hand, is an international standard that sets out requirements for metallographic specimen preparation. These standards ensure the consistency and comparability of metallographic analysis results across different laboratories and industries.

Let's break down the key indicators one by one:

The flatness of the work disk is a critical parameter that affects the quality of specimen preparation. A non - flat work disk can lead to uneven grinding and polishing, resulting in inaccurate microstructure analysis. To detect the flatness, a micrometer can be used. Place the micrometer at different points on the work disk and record the readings. According to ASTM E3 and ISO 14609, the allowable deviation of the work disk flatness should be within ±0.05 mm. The following is a simple operation flow:

The rotational speed accuracy of the grinding and polishing equipment is also essential. An inaccurate rotational speed can affect the grinding and polishing efficiency and the quality of the specimen surface. A tachometer can be used to measure the rotational speed. The standard requires that the rotational speed error should be within ±1% of the set speed. Here are the steps for calibration:

Clamp compatibility is often overlooked but can have a significant impact on the accuracy of metallographic analysis. Incompatible clamps can cause the specimen to move during grinding and polishing, leading to data deviation. To verify clamp compatibility, check whether the clamp can firmly hold the specimen without causing deformation. Also, ensure that the clamp does not interfere with the grinding and polishing process. For example, the clamp should not cover the area to be analyzed on the specimen.

In laboratories and industries, there are some common misjudgment mistakes. One of the most significant issues is the data deviation caused by incompatible clamps. For example, if the clamp is too loose, the specimen may move during the process, resulting in uneven grinding and inaccurate microstructure analysis. On the other hand, if the clamp is too tight, it may cause deformation of the specimen, also affecting the analysis results. Therefore, users need to be cautious when selecting and using clamps.

To help users quickly and easily evaluate the compliance of their equipment, we provide a standardized verification process template. This template includes all the key indicators and operation steps mentioned above, allowing users to conduct self - inspections of their equipment efficiently. By following this template, users can ensure that their metallographic grinding and polishing equipment meets the requirements of ASTM E3 and ISO 14609 standards.

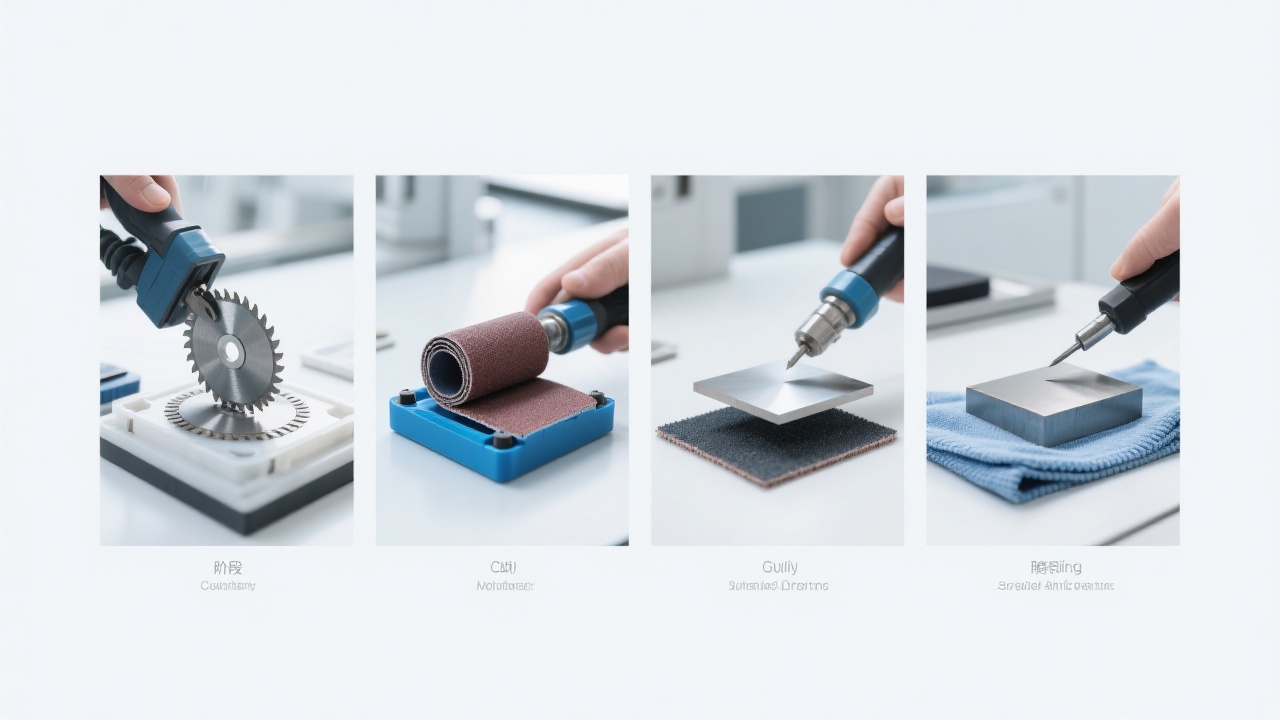

To enhance the expressiveness of the content, we recommend combining text with pictures and videos. Multimedia content can make the operation steps more intuitive and easier to understand. For example, a video demonstration of how to use a micrometer to measure work disk flatness can help users better master the operation skills. In addition, the use of data examples and references to international standard documents can enhance the credibility of the content.

This content can be flexibly applied in different marketing channels. By optimizing the content with SEO keywords such as "metallographic grinding and polishing machine standard inspection", "ASTM E3 standard verification method", etc., we can increase the search exposure of the content. This will attract more technical - oriented readers who are interested in metallographic analysis and equipment standardization.

Don't miss out on the opportunity to improve the accuracy of your metallographic analysis! Download our Metallographic Equipment Self - Inspection Checklist now or join our standardization practice community to stay updated with the latest industry knowledge and best practices.