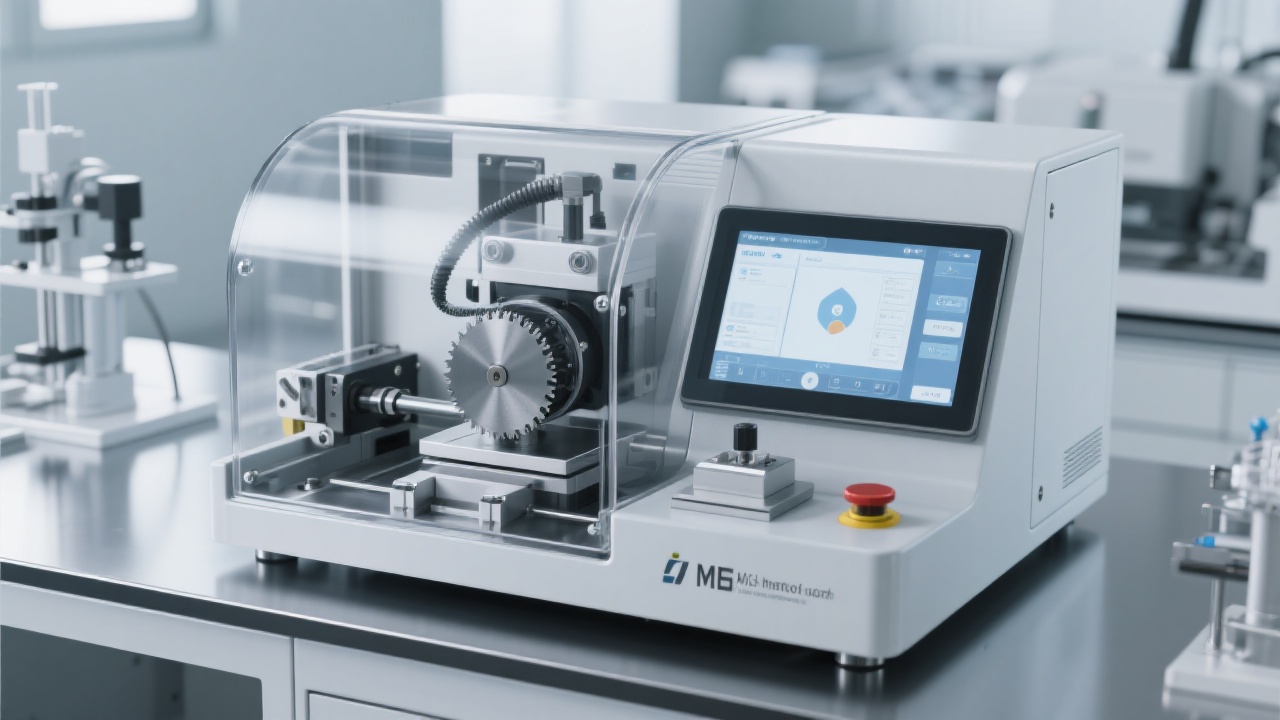

When it comes to metallographic sample preparation, consistency is king. The LMP-3 Metallographic Grinder-Polisher is engineered to deliver precision and repeatability, but it’s your mastery over the speed settings and process parameters that drives optimal results. Whether you’re a novice or a seasoned engineer, understanding how to tailor your grinding and polishing approach according to material characteristics is essential to achieving high-quality surface finishes with minimal defects.

Before diving into advanced tweaks, familiarize yourself with the LMP-3’s user-friendly LCD interface and basic operational workflow. This machine is designed with an intuitive display that facilitates easy setting adjustments and real-time monitoring of speed, time, and pressure. Ensure samples are securely mounted to avoid uneven polishing, which could compromise surface uniformity. Always perform a quick safety check—proper grounding, secure guards, and appropriate PPE must be in place. Safety is your first step towards precision.

Material-specific speed settings are the cornerstone of consistent results. Different substrates respond uniquely to grinding and polishing forces. Here’s a practical speed reference you can adapt:

| Material | Recommended Speed Range (RPM) | Optimal Process Notes |

|---|---|---|

| Metals (Steel, Aluminum) | 150 - 250 | Moderate speed prevents overheating; use stepped polishing to reduce deformation |

| Ceramics | 100 - 180 | Lower speeds avoid cracking; gentle polishing suspensions recommended |

| Composite Materials | 120 - 200 | Balanced speeds reduce delamination risks; incremental steps advised |

Just a few tweaks can make all the difference. By adjusting the speed to the specific material, you mitigate surface damage while optimizing throughput.

Routine maintenance ensures longevity and reliable performance. Develop a cleaning schedule to remove debris and polishing residues after every session. Consumables like polishing cloths and abrasive discs should be replaced in alignment with manufacturer recommendations - generally every 40-60 hours of use. Be alert to unusual noises or irregular speed variations; these often hint at bearing wear or belt slippage. Early detection and intervention prevent costly downtime.

When handling batches, loading multiple samples at once is a proven strategy for maximizing throughput without compromising precision. The LMP-3 supports parallel processing modes—configure your workflow to overlap preparation phases effectively. Additionally, leverage the energy-saving modes built into the machine to reduce operational costs while maintaining performance consistency.

Design a standardized operation procedure for your team, incorporating these multi-sample and eco-friendly tactics to scale results efficiently.

Have you experimented with different speed settings or polishing consumables on your LMP-3? Leave your questions or tips below—we’re here to help you perfect every step. Don’t waste time on guesswork; just a few minutes mastering these core techniques will put an end to repeated trial and error.