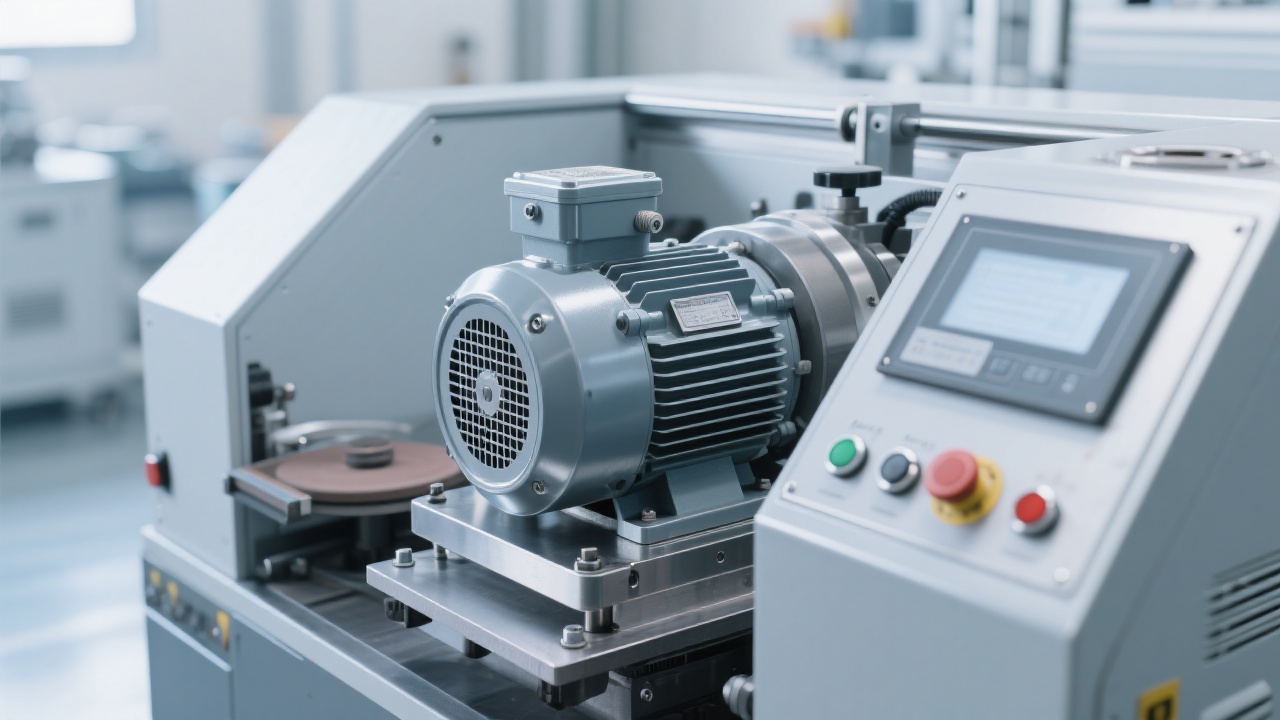

Did you know that over 60% of unplanned downtime in metallography labs stems from preventable maintenance issues? Whether you're managing a university research facility or an industrial QA lab, consistent performance of your polishing machines is critical—not just for sample quality, but also for productivity and cost control.

Start with the basics: clean the grinding wheel and polishing cloth after each use. A simple wipe-down using isopropyl alcohol removes residual metal particles that can cause micro-scratches on your samples. For high-volume users, schedule a full inspection every two weeks—especially checking belt tension and motor vibration levels. According to ISO 14675-1 standards, even minor misalignment can reduce tool life by up to 30%.

Unusual noise, shaking during operation, or inconsistent rotational speed are often early indicators of deeper problems—like worn bearings, damaged gears, or electrical imbalances. In one case study from a German automotive materials lab, engineers caught a failing drive motor through temperature monitoring alone, avoiding a $12k repair bill and saving 3 weeks of production delay.

Pro tip: Keep a logbook. Record daily operating hours, material types used, and any anomalies. This data helps identify patterns—such as increased wear when processing hardened steel versus aluminum—which informs better scheduling and part replacement cycles.

Many modern metallography systems feature GRP enclosures for chemical resistance—but they’re not immune to degradation. Salt spray exposure, frequent cleaning agents, and humidity can all lead to surface cracking over time. Apply a silicone-based protective coating every 6 months in humid environments (like Southeast Asia labs), and inspect quarterly for micro-cracks near joints or vents.

When it comes to consumables like polishing cloths and grinding discs, choose brands known for consistency—such as Buehler’s “Buehler Polishing Cloth Series” or Struers’ “Tegramin” line. These aren’t just marketing claims—they’ve been tested across hundreds of labs worldwide and show minimal variation in grit retention over 50+ uses.

Remember: effective maintenance isn’t about reacting—it’s about anticipating. With structured routines, clear documentation, and smart material choices, your lab can achieve 95% uptime and significantly lower long-term operational costs.