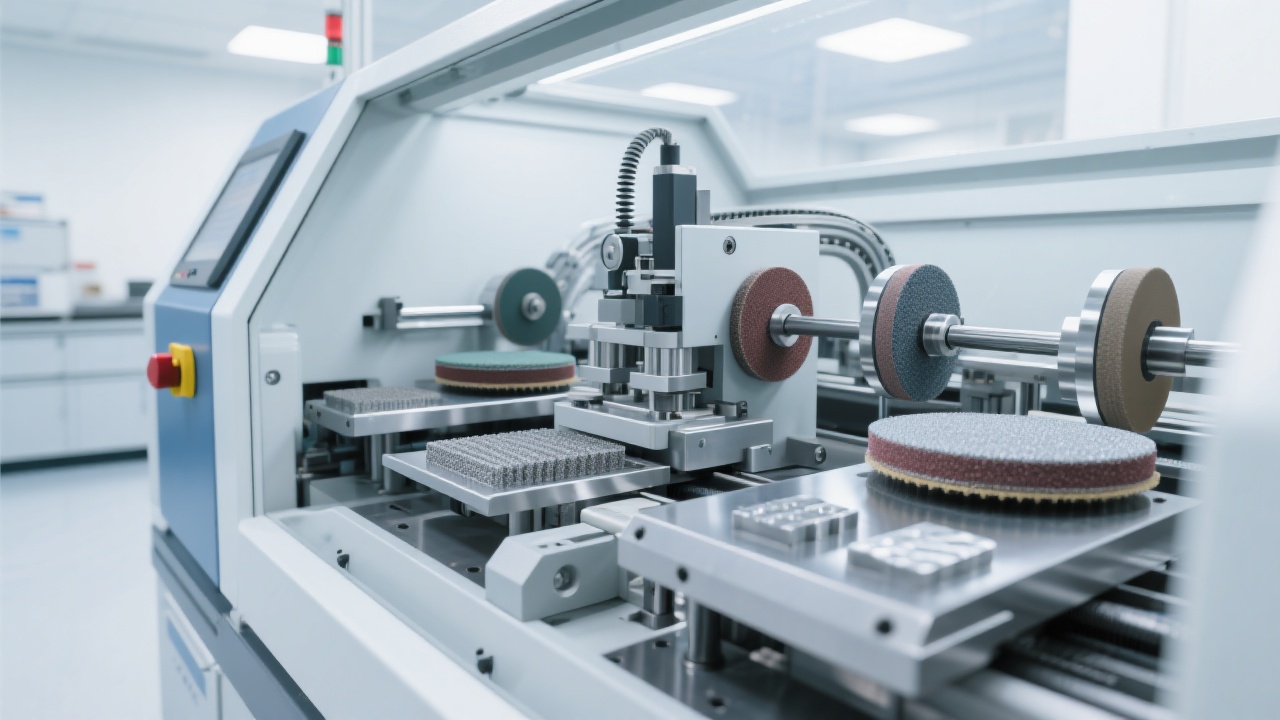

Unlock efficient, low-damage sample preparation with the Q-2A Metallographic Cutting Machine

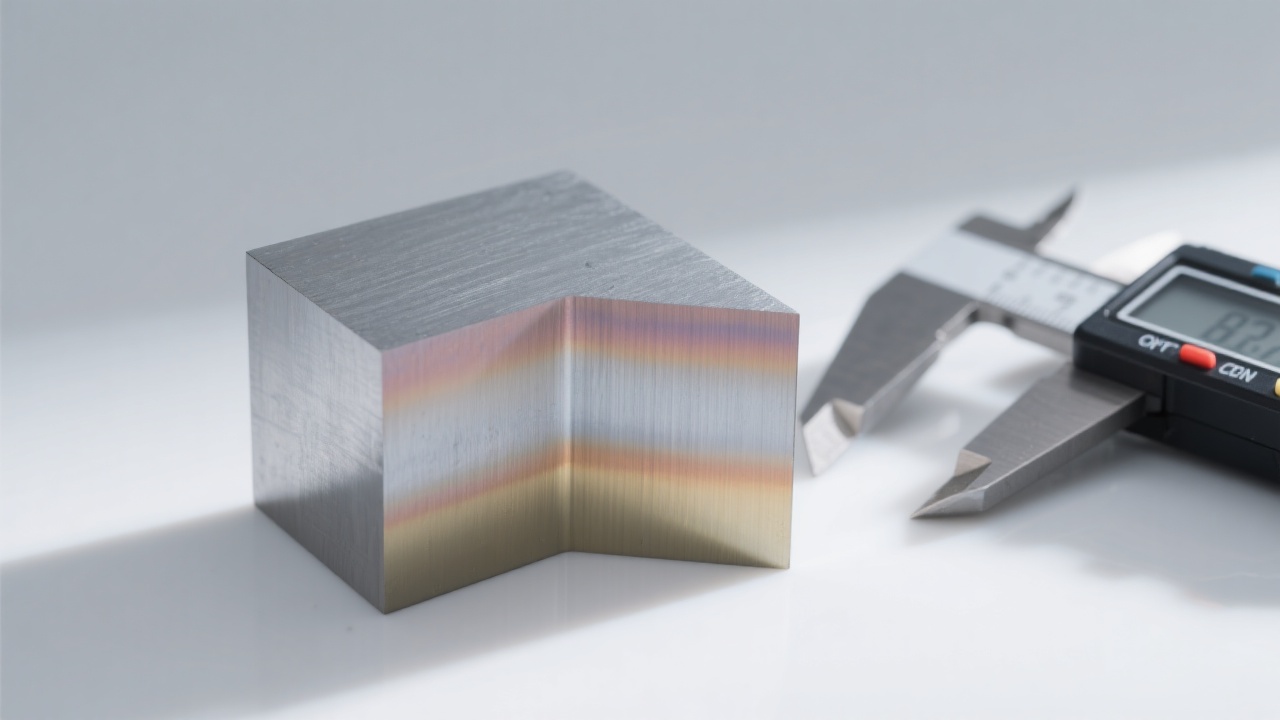

The Q-2A model is engineered to meet diverse metallographic sample preparation demands. Its maximum cutting diameter is 50 mm, making it suitable for a variety of sample sizes. It operates at a stable spindle speed of 2800 revolutions per minute (r/min), optimized for both metallic and non-metallic materials such as stainless steel, ceramics, and cast iron.

| Parameter | Specification | Application |

|---|---|---|

| Cutting Diameter | Up to 50 mm | Varied sample sizes |

| Spindle Speed | 2800 r/min | Optimal cutting speed for metals & ceramics |

| Wheel Type | High-speed reinforced grinding wheel | Enhanced durability & surface finish |

One key innovation of the Q-2A lies in its advanced cooling and heat dissipation system. By maintaining optimum temperature control during cutting, it reduces thermal stress and minimizes heat-induced sample damage such as surface burning and deformation. This prolongs the grinding wheel’s life expectancy by up to 30% compared to conventional machines without optimized cooling.

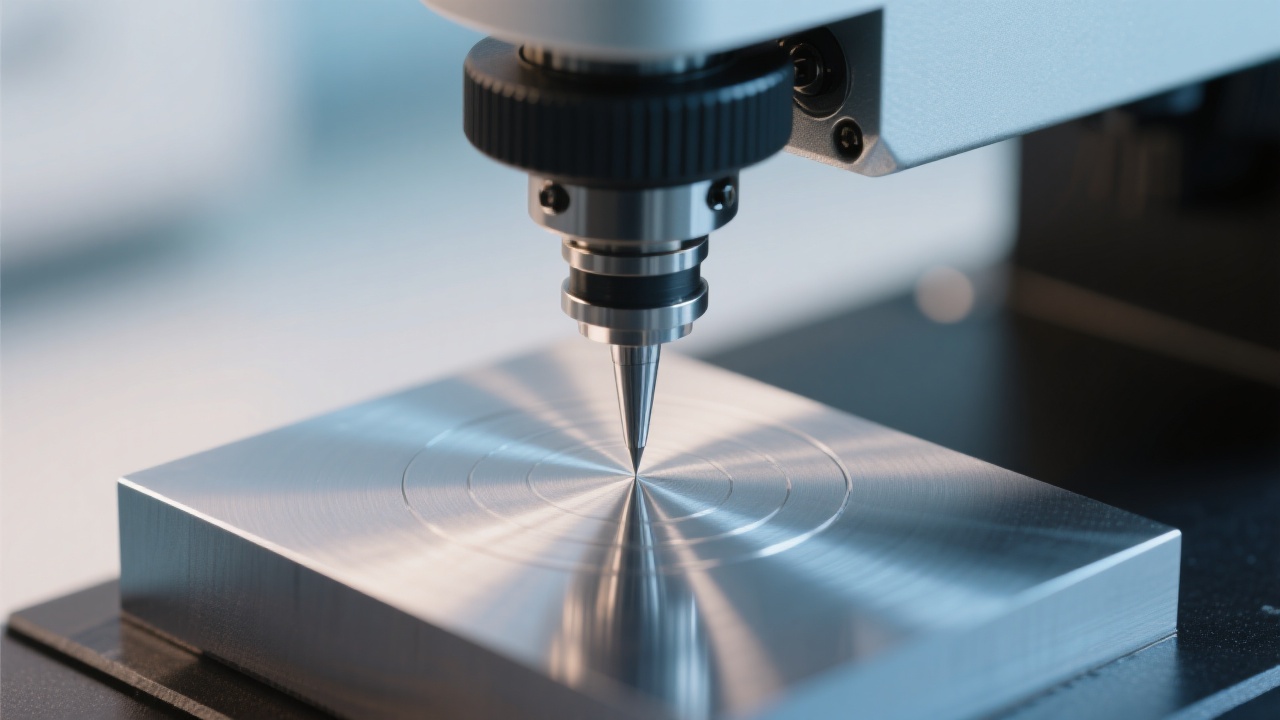

According to ASTM E3—19 guidelines for metallographic specimen preparation, controlled cooling is critical for preserving sample integrity during abrasive processes.

ASTM E3—19 (Standard Guide for Preparation of Metallographic Specimens):

Emphasizes the importance of coolant usage to prevent microstructural damage induced by thermal effects during cutting.

The integration of a high-speed reinforced grinding wheel with an innovative cooling system ensures high cutting efficiency while drastically reducing sample alteration risks.

Compared to traditional abrasive wheels and air-cooled designs, the Q-2A shows:

This model is certified against ISO 4520 and complies fully with ASTM standards, providing assurance for laboratories worldwide.

ISO 4520 (Metallic Materials—Metallographic Cutting Machines):

Sets stringent requirements on cutting accuracy, repeatability, and equipment safety.

Such compliance guarantees that Q-2A users receive consistent and repeatable sample preparation results — a critical factor for quality control in industries like aerospace, automotive, and electronics.

Several typical concerns include:

| Issue | Cause | Recommended Solution |

|---|---|---|

| Surface Burn Marks | Insufficient cooling or excessive feed rate | Adjust cooling liquid flow rate; reduce feed speed |

| Specimen Deformation | Incorrect clamping or worn grinding wheel | Ensure proper fixture setup; replace grinding wheel when worn beyond 20% diameter |

| Poor Repeatability | Lack of regular calibration | Perform calibration checks every 3 months using standardized samples |

Routine maintenance is vital for sustained performance:

Coolant choice depends on specimen type:

Maintaining proper coolant viscosity around 30–40 cSt at 40°C ensures effective heat dissipation without excessive fluid consumption.

Grinding wheels should typically be replaced when the diameter has worn down by approximately 20% or when surface finish quality noticeably deteriorates, whichever comes first. Early replacement prevents sample distortion and maintains cutting precision.

Thanks to its flexible spindle speed and compatible grinding wheels, the Q-2A accommodates: