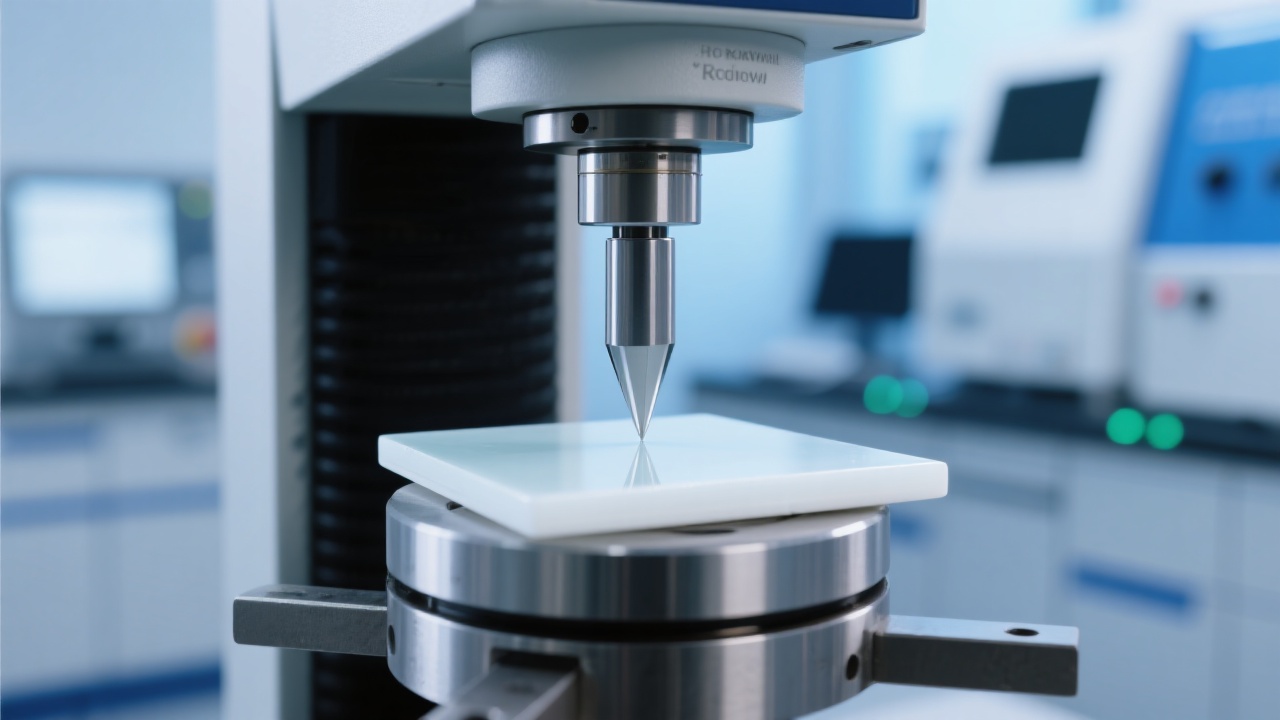

In the world of laboratory metal sample preparation, a high - efficiency and stable metallographic grinder - polisher is the key to ensuring the quality of samples. The MP - 160E metallographic grinder - polisher from Laizhou Jincheng Industrial Equipment Co., Ltd. is a remarkable device, and this article will provide a systematic guide on its maintenance and upkeep.

Regular daily maintenance is the foundation for the long - term stable operation of the MP - 160E. First, the cleaning process is crucial. After each use, clean the equipment thoroughly to remove any residues from the grinding and polishing process. For example, use a soft brush to clean the grinding disc and the surrounding areas to prevent the accumulation of debris, which can affect the accuracy of subsequent operations.

The replacement cycle of grinding and polishing materials also needs attention. Generally, it is recommended to replace the grinding discs every 50 - 100 uses and the polishing materials every 30 - 60 uses, depending on the intensity of use. This ensures that the equipment can always maintain high - quality sample preparation results.

The MP - 160E features a fiberglass shell, which has excellent corrosion - resistant properties. However, to further enhance its lifespan, proper protective measures are necessary. Using high - quality anti - corrosion coatings can significantly improve the shell's resistance to chemical substances. For instance, applying a layer of anti - corrosion paint every 6 - 12 months can effectively prevent corrosion. Additionally, using protective covers when the equipment is not in use can also reduce the risk of damage.

There are some recommended protective products in the market, such as special fiberglass protective films. These films can not only prevent scratches but also provide an additional layer of anti - corrosion protection.

Regular monitoring of the transmission system and motor is essential to detect and address potential issues early. When checking the transmission system, pay attention to common early - stage fault signs, such as abnormal noises, vibrations, or speed irregularities. For example, if you hear a rattling sound during operation, it may indicate a loose part in the transmission system. In such cases, immediately stop the equipment and conduct a detailed inspection.

For the motor, check its temperature regularly. A motor that runs too hot may be overloaded or have a ventilation problem. If the motor temperature exceeds 60°C during normal operation, it is necessary to stop the machine and find the root cause. Also, monitor the motor's current. An abnormal increase in current may suggest a short - circuit or other electrical problems.

Let's take a look at a user case. A laboratory in the United States has been using the MP - 160E for several years. By following the proper maintenance procedures, they have significantly reduced the equipment's downtime. The laboratory's technician said that "Regular maintenance has not only extended the lifespan of the equipment but also improved the quality of our sample preparation."

In addition, this article also provides an analysis of industry standards and shares some maintenance experiences to enhance the content's authority. Adhering to industry standards ensures that your equipment maintenance is scientific and effective.

Q: How often should I clean the MP - 160E? A: It is recommended to clean the equipment after each use to prevent residue accumulation.

Q: What should I do if I find abnormal noises in the transmission system? A: Immediately stop the equipment and conduct a detailed inspection to identify and fix the problem.

We encourage you to leave your comments and questions below. Your participation will help us improve the content and provide better guidance. 😊

Laizhou Jincheng's MP - 160E metallographic grinder - polisher is known for its high - quality performance and reliable after - sales service. By following the maintenance tips in this article, you can ensure the long - term stable operation of your equipment. If you want to learn more about Laizhou Jincheng's products and accessories, click here.