In the field of metal material hardness testing, common data deviations in Brinell hardness testing often stem from unclear understanding of standards or non - standardized operations. This article delves deep into the key differences between two core standards, GB/T 231.2 and ISO 6506, aiming to help quality engineers and researchers enhance testing accuracy and report compliance, ensuring the mutual recognition of results in the industry.

These two standards have notable differences in indentation measurement, load application, and specimen preparation. For example, in indentation measurement, the measurement accuracy requirements and methods may vary. According to a study, nearly 30% of measurement errors in Brinell hardness testing are related to differences in standard requirements for indentation measurement.

In terms of load application, ISO 6506 might have different requirements for load stability and application time compared to GB/T 231.2. These differences can lead to significant variations in test results if not properly understood and followed.

Let's look at some typical error cases. Incorrect indenter selection, unstable load, and environmental temperature and humidity interference are common high - frequency errors. For instance, using an incorrect indenter can result in inaccurate hardness values, which may lead to misjudgment of material quality.

Standard Clause Summary: GB/T 231.2 clearly stipulates the requirements for indenter selection based on different material types and hardness ranges. ISO 6506 also has its own set of rules, which may differ slightly from GB/T 231.2.

When such errors occur, it is crucial to follow the correct handling procedures. First, identify the root cause of the error. Then, adjust the testing parameters or conditions according to the corresponding standard requirements. Finally, repeat the test to ensure the accuracy of the results.

Standardized operations play a vital role in the quality control loop. In real - world applications, problems like poor laboratory repeatability and customer doubts about data validity are often caused by non - standardized operations. By strictly following the standards, we can minimize these problems and ensure the reliability of test results.

For example, a metal manufacturing company reduced its test result error rate from 20% to less than 5% after implementing strict standard - compliant operations.

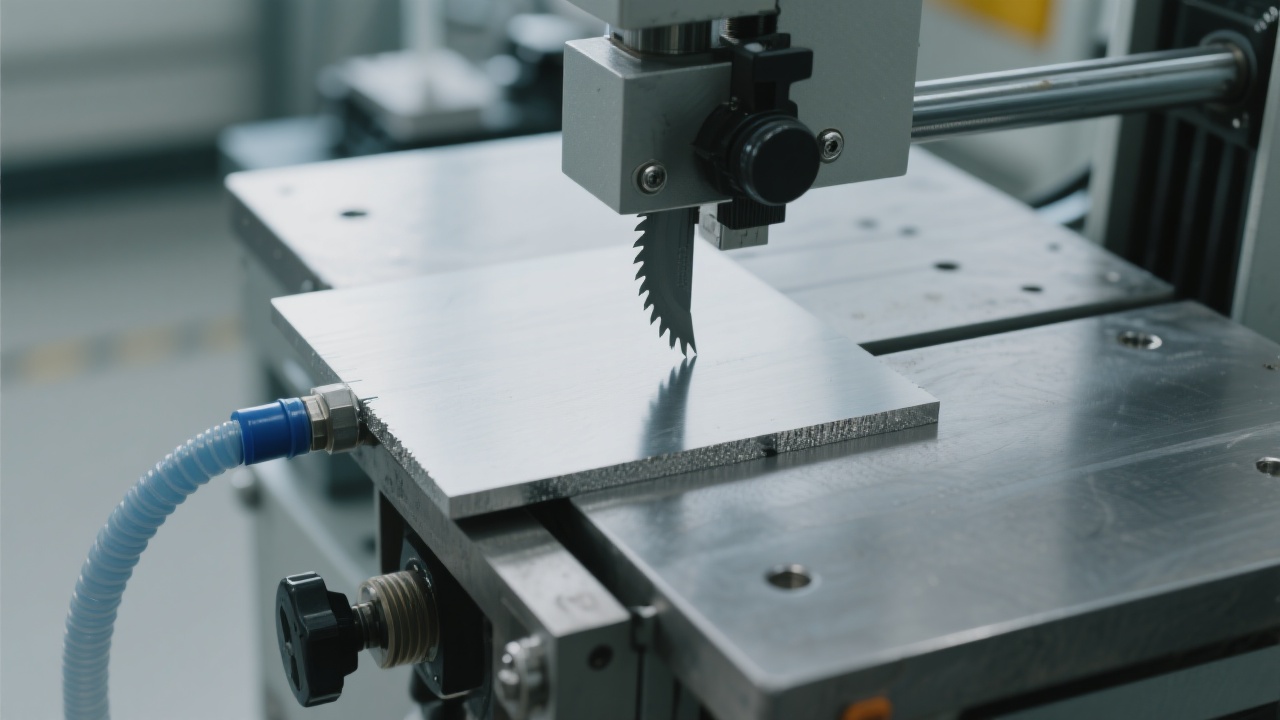

To enhance the enforceability of standard compliance, we introduce a practical checklist. This checklist includes items such as indenter inspection, load calibration, and environmental condition monitoring. By using this checklist, users can ensure that each step of the testing process meets the standard requirements.

You may wonder, “Have I encountered similar problems in my hardness testing work?” If you do, it is time to re - evaluate your testing process against these standards. Learn more about authoritative testing methods by referring to official standard documents or contacting our technical support for guidance.