In the aerospace and heavy machinery industries, precise and reliable material hardness testing is non-negotiable. Laizhou Jincheng Industrial Equipment Co., Ltd. presents its cutting-edge fully automatic magnetic Rockwell hardness tester, engineered to meet stringent testing requirements while delivering consistent operational stability. This advanced equipment integrates innovative sensor technologies and intelligent control systems, making it an indispensable solution for aerospace manufacturers committed to quality assurance and traceability.

At the heart of this hardness tester lies a high-precision load sensor capable of detecting applied forces with an accuracy better than ±0.1%. Coupled with an intelligent force control system, the device maintains load application within strict tolerances, effectively minimizing measurement error. This precision aligns seamlessly with the GB/T 230/231 national standards for Rockwell hardness testing, ensuring results that are both reliable and replicable for high-stakes aerospace components.

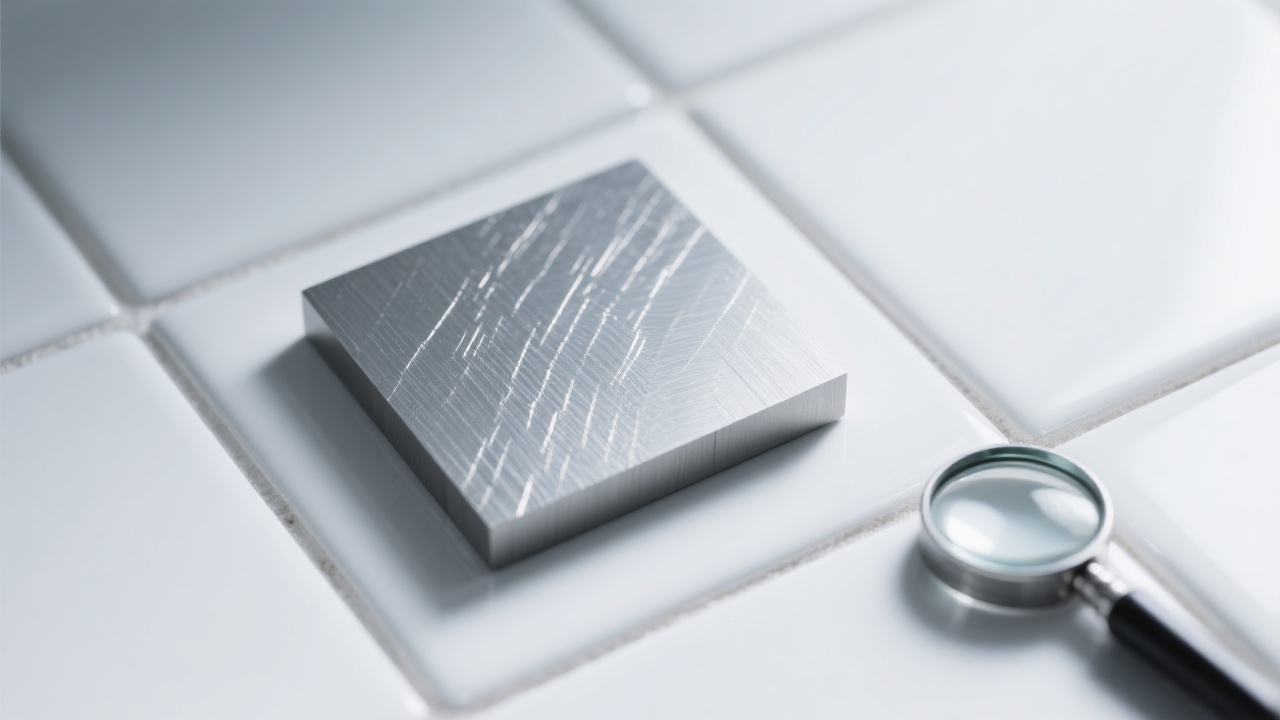

Compliance with national standards such as GB/T 230 (Rockwell hardness test method) and GB/T 231 (Rockwell hardness test equipment) is a benchmark of testing integrity. Our magnetic Rockwell hardness tester's design and calibration procedures ensure that deviations stay within ±1 HRB (Rockwell hardness points), verified through repeated tests on standard reference blocks. Such adherence solidifies the equipment’s place in critical aerospace quality control environments where measurement confidence is paramount.

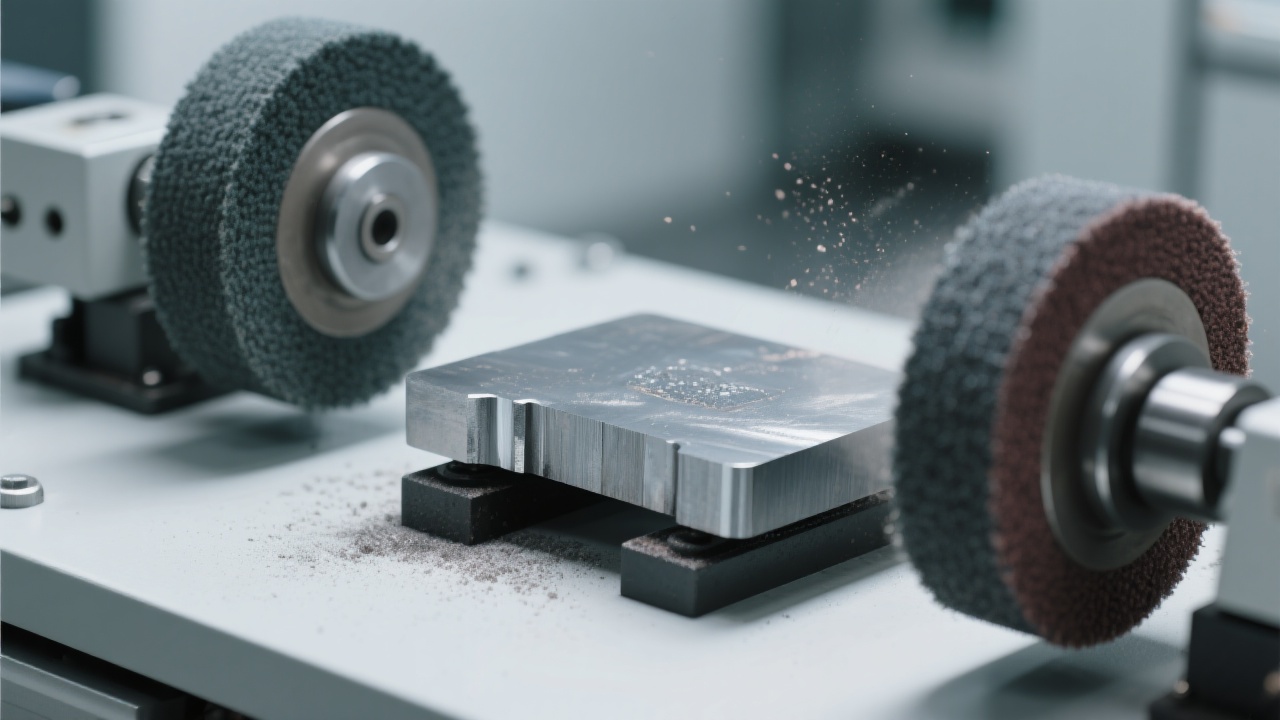

A standout feature is the magnetic chuck system engineered for swift, non-destructive attachment to large, complex steel workpieces. This enables rapid hardness assessment directly on aerospace-grade metals without sample removal, reducing downtime and handling errors. The magnetic force is optimized to ensure secure holding under test conditions, even on irregular geometries, thus facilitating seamless integration into existing production lines or maintenance workflows.

For traceability and quality assurance, the tester supports Bluetooth wireless data transfer to PCs, tablets, and mobile devices, enabling real-time monitoring and remote data analysis. It can internally store up to 1,000 discrete test records, complete with timestamps and operator IDs. This feature streamlines audit processes and facilitates continuous improvement through detailed trend analysis—a critical demand in aerospace quality workflows.

Purchase confidence is reinforced by the provision of original manufacturer components, ensuring long-term integrity and consistent performance. Laizhou Jincheng’s dedicated technical team oversees professional installation and calibration services on-site, followed by comprehensive after-sales support, including routine maintenance, technical troubleshooting, and software updates. This full lifecycle approach guarantees uptime critical for B2B clients in the aerospace manufacturing sector.

Addressing common pain points such as measurement drift, equipment downtime, and traceability gaps, this hardness tester offers aerospace manufacturers a robust quality control cornerstone. The convergence of accuracy, rapid on-site testing, and integrated data management elevates inspection workflows, enabling faster decision-making and reducing rework rates by as much as 15% according to internal case studies.

Priced strategically within the mid-to-high segment of the industrial hardness tester market, this product balances cost-efficiency with premium features. Buyers realize a compelling return on investment through decreased inspection times, minimized labor costs, and enhanced product quality. The transparent pricing, backed by rigorous technical validation and brand reputation, further drives buyer confidence in the B2B aerospace domain.

The company commits to ongoing R&D and periodic firmware enhancements, directly informed by frontline aerospace quality control feedback. Clients benefit from timely knowledge transfer about evolving standards and best practices, allowing adaptation to emerging materials and testing scenarios.